Developments with my waste oil burner

UPDATE 08/12/2020 New design with much cheaper nozzle.

The new design uses a nozzle that was £12 including world wide delivery. 1.0 mm nozzle: http://bit.ly/2RtjQpC

I have been toying with trying an oil burner in my for a while now.

There are two popular methods used by backyard metal casters, drip feed and siphon feed.The new design uses a nozzle that was £12 including world wide delivery. 1.0 mm nozzle: http://bit.ly/2RtjQpC

I have been toying with trying an oil burner in my for a while now.

I thought a siphon would be more controllable and cleaner to use.

I imported a Hago siphon nozzle and adapter from the US, we don't have anything similar in the UK. The oil is fed into one part and compressed air into a second entry. It works on the same principle as a spray gun. The oil comes out in an extremely fine mist which can be ignited.

I wanted to fit it into a 2" tube as that would fit into the existing tuyere in my home made furnace so I had to make a smaller elbow fitting for the oil inlet, the one supplied would not allow the nozzle to be centred. Ebay provided some nice small (and cheap) needle valves from China, one for oil and one for air.

I made up some pipe fittings and connected up to some tube.

A plumbing waste Tee was used at the rear and an aluminium plug made to seal the pipe entry.

Three strips of stainless sheet made a fitting to hold the nozzle centred in the tube.

A blower is also needed to supply combustion air for the burner.

I had this tangential fan I thought I could use, I didn't want the noise of a shop vac running for a couple of hours on a long pouring session.

I only had the actual fan not the housing so I made up a trial cardboard housing to check I had the shape right.

Results were good, I coupled it up to a high quality 12v motor I had and fed it from an old adapted computer power supply.

Happy with the performance next step make up an MDF and card housing.

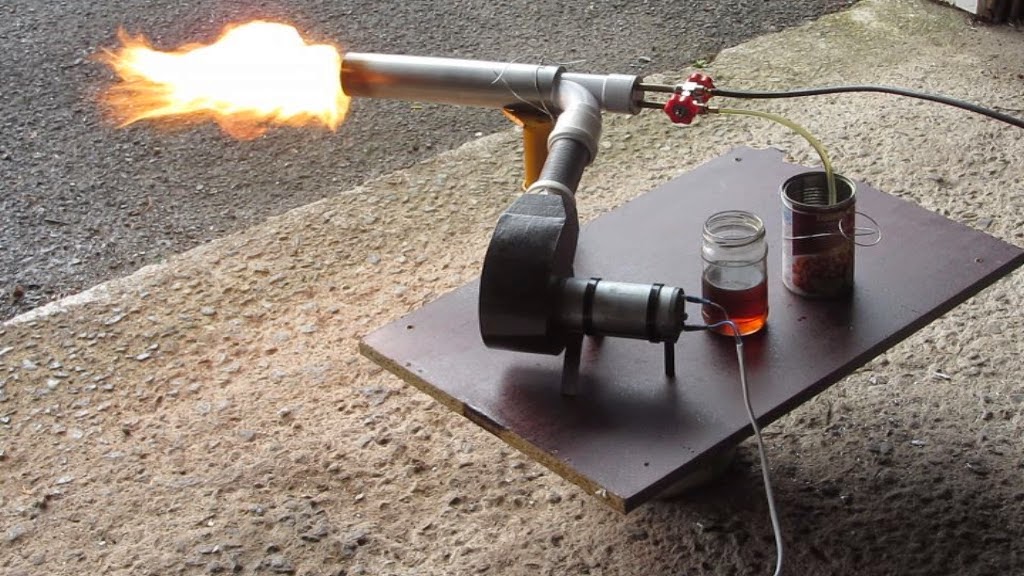

First firing.

Using 5-10 psi on the nozzle and kerosene for fuel I had no problem lighting the burner with a weed burner.

Next a trial in the furnace.

I was amazed how easily it went, nice swirly flame around the crucible.

After a while I transferred the fuel feed to some new engine oil, as soon as the oil hit the burner the flame went out!

The engine oil is thicker than the kerosene so I warmed the oil a little, it was about 5 deg Centigrade outside, and increased the air pressure to the nozzle.and tried again. Wow! it was like turning on the booster rocket.

I was just going to see how the burner went but as it was going so well i tossed in some aluminium, it seemed to melt in no time although I did not record the actual time.

Video of the burner construction

I am very pleased with the results, next sort out a fuel tank and get some waste oil to try, this will give the furnace a very low running cast.

I haven't tried elevating the fuel tank, maybe it will be necessary when I try waste oil but I like the idea of the burner above the supply so fuel only appears when the air is on.

Update 04/12/14

I added a spin vane in place of the metal bracket. Some builders have mentioned that they are not sure if this makes any difference to performance, which is why I tried it without, but it does seem to make the flame more controllable.

The theory is that is make the air spin as it leaves the tube.

Update 11/12/14

I made a new fitting to fit at the rear of the burner. This replaces the plastic tee.

I have also added a ball lever valve so the fuel can be shut off without altering the needle valve setting.

I now have supply of waste motor oil. I filtered it through a scotchbrite pad to clean it up.

I put my propane burner in the furnace for about 5 minutes to pre heat it.

I had the fuel tank about 5ft high and lit with a weed burner. To my surprise it lit straight away and after playing with the different settings found it is very controllable.

5 psi is enough for the air line, I could turn it down to 2 psi without it going out. I can turn off the fuel with the ball valve and it stops immediately, turn it back on and it instantly relights, it's just like using propane.

I had wondered if using oil would leave black deposits or stains inside the furnace but it is completely clean, there is no smoke and, and it's pretty quiet.

5 psi is enough for the air line, I could turn it down to 2 psi without it going out. I can turn off the fuel with the ball valve and it stops immediately, turn it back on and it instantly relights, it's just like using propane.

I had wondered if using oil would leave black deposits or stains inside the furnace but it is completely clean, there is no smoke and, and it's pretty quiet.

Update 20/12/14

I have removed the spin vane and replaced it with a simple fitting to centre the nozzle.

Further tests showed the burner functions better without it.

I have made a fuel tank from a mop bucket and mounted it on the wall.

It holds about 12 Lt of oil and can be stood on top of a single ring electric ring to warm the oil in cold weather.

The brass tube in the front centre allows a thermometer probe to used to measure the oil temperature. It was about 5 deg C when the tests were made so the oil was heated to about 25C so it could flow better.

To the left is a fuel gauge and ball valve on/off control.

I have made up a filter to clean the waste oil. Oil can be pumped from the waste container and passes though a car oil filter into my fuel tank.

This video shows the final version, fuel tank and filtering system

Propane Burner

Details of my propane burner can be found on the Furnace page.