I recently received this machine with a view to learning CNC machining.

I will be describing the assembly, software installation and use of the machine on these pages.

The machine is extremely well designed and can produce some stunning work.

My machine also has a laser cutter, it is available with or without this option.

The video on Banggood's website shows a previous model which has MDF panels in the construction. The latest version now has strong and rigid acrylic panels. When assembled with the generous section extrusions between them, the tool is very rigid. The X, Y and Z axis run smoothly on linear ball bearings and I can feel no backlash on the leadscrews. This is achieved with the use of 2 leadscrew nuts pre-loaded with adjustable springs.

The wood and plastic parts I have made can be used as patterns for casting. I will be trying this next.

Examples of my efforts so far are shown below.

Dragon engraving using a design supplied with the machine.

It is extremely detailed.

Gear cut in 4mm plywood.

Myfordboy keyfob CNC engraved in ABS.

Casting made from the engraved pattern.

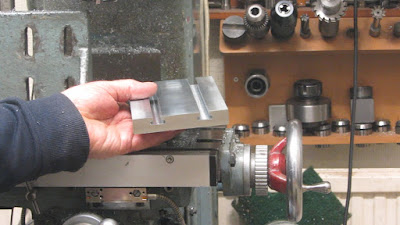

My idea is to replace the spindle supplied with the tool, which is quite suitable for wood, with a much larger, more powerful one. This will involve making a new Z carriage and replacing the Y axis rods and linear bearings with some larger ones.

The construction of the machine means no existing parts will be harmed during the conversion.

The machine is supplied ready to assemble, all the parts are high quality, the fixings are

stainless steel.

stainless steel.

The supplied spindle (top) and the larger one I will replace it with.

The machine is supplied with 2 20° engraving cutters.

I also have a set of carbide end mills and some ball nose cutters and These engraving cutters to try.

Special offers on other CNC parts at Banggood.com click HERE

This is the link to the new spindle ,click HERE

Video

Assembly

The instructions are in the form of a series of photos which are downloaded from the link given on the Banggood sales page

They cover the build well and were easy to follow although I did make a few mistakes and had reassemble the parts.

There are some hex keys supplied with the kit that fit the stainless screws the machine is assembled with. I soon found with the large number of screws to fit it was time to get out my

set of hex bits that fit in a screwdriver type handle. Also an essential tool to have is a small spanner to fit the self locking nuts.

The first instruction Number (0) shows how two leadscrew nuts are fitted to give anti backlash to the leadscrews. I made this part first, the system works well and I could feel no backlash on the nuts.

When I assembled the other leadscrews though I followed the instructions and the backlash nut is not show so I forgot about it until I noticed there were some still in the packaging.

There are plenty of screws and fittings supplied and there were quite a few spares left at the end.

The 3 mm screws come in 2 lengths but I soon ran out of the shorter ones. Longer ones can be used for all the assembly but you need to keep back the short ones for fitting the motors as I found out later.

I also found the 5 mm ones were a little long and bottomed out when fitting the panels to the extrusions so I shortened them.There were plenty of washers left at the end, (referred to in the instructions a shims) so instead of shortening the screws the washers could be used under the screw heads.

Ball bearings are used at each end of the X axis screw and I found these were a little loose in the panels but some thin tape wrapped around made them secure. Loctite could have been used as an alternative.

Another mistake I made was to fit the Y carriage the wrong way around, easily corrected though, only 4 screws involved.

At the end of the mechanical construction I found there were 4 blue anodised cone shaped spacers left. These had not been mentioned in the instructions but referring back to the sales page I noticed they were supposed to be used under the X axis motor fixings.

The control board supplied was different to the one shown, an improved version. I was not sure of the connections but a search on the Banggood site showed the controller for sale as a separate item and connections which shown there.

On the board there is a potentiometer for each axis. Adjusting these will increase the current to the motor for more power but I have not found it necessary to alter these.

On the board there is a potentiometer for each axis. Adjusting these will increase the current to the motor for more power but I have not found it necessary to alter these.

Overall impression

The design is very well thought out. The acrylic sides and aluminium extrusions make a very rigid construction. There is no play in the leadscrews. The spindle is small and only allows small cuts.

This is my first experience with CNC and I have enjoyed learning and using the machine.

I now have the larger spindle mentioned earlier fitted and have been able to cut 1/8 brass using this. More modifications to follow.

The spindle/controller I bought can be only used in AC220V±10% 50/60Hz, so it is not suitable for 110v but read the notes on the alternative controller I am now using, later on this page.

The motor needs 100v to power it.

The motor needs 100v to power it.

Milling brass sheet.

Video

Video

I had a few problems installing the software with various error messages appearing when following the instructions but a friend and fellow modeler in Canada was able sort it out for me despite being 3800 miles away.

He has very kindly written the details below.

Banggood seem to have changed the link to the software and you are now directed to the Eleksmaker site which does not seem to very helpful to me.

Email me if you would like the old link.

He has very kindly written the details below.

Banggood seem to have changed the link to the software and you are now directed to the Eleksmaker site which does not seem to very helpful to me.

Email me if you would like the old link.

22/05/17

The machine is finished.

I have had a few problems with the spindle/controller causing electrical interference and

causing the programs to crash.

If you look around Youtube there are others with the same spindle having similar problems.

The suggestions include, use a short screened USB cable, fit capacitors across the motor terminals, use an optical isolator in the USB line,and fit ferrite beads to the leads.

I had tried all these and was still getting problems.

The capacitors are a no no. The power supply uses pulse wave modulation and it is not pure DC at the terminals. They get hot very quickly.

The optical isolator I tried just crashed the computer as soon as it was plugged in, maybe I had a faulty one.

I began to think the problem is the controller and not the spindle so I now have it running from a variac, bridge rectifier and smoothing capacitor circuit.

The variac enables speed control still but as I can't see the spindle being run at anything other than maximum speed this could be replaced with a basic transformer. An 80 volt transformer secondary and 2 x 4700 MFD 250v capacitors give 102 volts at the motor, same as max power with the Banggood controller.

I have 3 x 0.1 MFD ceramic capacitor on the motor terminals. One across the + and - and one from each lead to the frame of the machine which is also connected to the domestic earth supply.

The spindle draws 0.4 amps DC and the load from the mains supply is 0.75 amps. I don't know where the 500w spindle rating comes from.

So far there has been no further problems so hopefuly the problem is solved.

27/05/17

Banggood now have a new improved design of nut an as they are so cheap I have bought some to replace the original if any backlash develops..

Left, original nuts, right new ones.

The new design can been bought HERE at the time of writing there is a promotion on similar products https://goo.gl/HLK0fm